Introduction:

In the dynamic world of industrial automation and material handling,

circular belt conveyors have emerged as key players, offering innovative solutions for efficient transportation within manufacturing facilities and distribution centers. This article explores the design, applications, and advantages of circular belt conveyors, highlighting their pivotal role in streamlining material handling processes.

Design and Components:

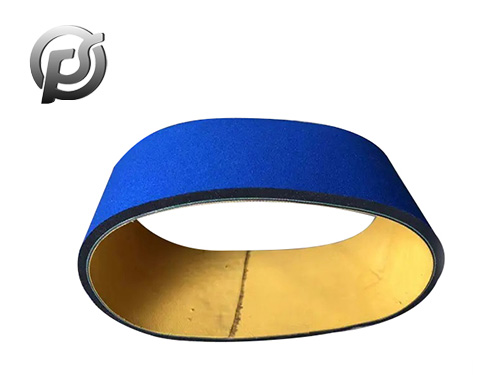

Circular Belt Configuration:

Circular belt conveyors are characterized by their circular layout, where the belt forms a closed loop. This design allows for continuous and smooth movement of materials in a circular path, optimizing space utilization and facilitating seamless material flow.

Drive Systems:

Circular belt conveyors are powered by various drive systems, including electric motors or motorized pulleys. These drive systems ensure a controlled and consistent movement of the conveyor belt, contributing to the overall efficiency of material transport.

Rollers and Idlers:

The conveyor belt runs on rollers and idlers that support and guide its movement. These components are strategically placed to minimize friction, reduce wear and tear, and maintain the stability of the conveyor system.

Applications in Material Handling:

Sorting and Accumulation:

Circular belt conveyors are widely used in sorting and accumulation processes. They enable the controlled movement of items in a circular path, allowing for accurate sorting and accumulation of products before being directed to their respective destinations.

Assembly Lines:

In manufacturing assembly lines, circular belt conveyors play a crucial role in transporting components between different stages of production. Their continuous loop design ensures a smooth and efficient flow of materials, contributing to streamlined assembly processes.

Distribution Centers and Warehousing:

Circular belt conveyors are employed in distribution centers and warehouses for tasks such as loading and unloading goods. Their ability to navigate tight spaces and transport materials in a circular path makes them valuable in optimizing storage and retrieval operations.

Advantages of Circular Belt Conveyors:

Space Efficiency:

The circular layout of these conveyors allows for efficient use of space, making them suitable for facilities with limited floor space. The compact design enables the creation of intricate material handling systems in confined areas.

Continuous Material Flow:

Circular belt conveyors provide a continuous and uninterrupted material flow, eliminating the need for start-stop operations. This continuous movement enhances overall system efficiency and minimizes the risk of bottlenecks in material handling processes.

Flexibility and Adaptability:

Circular belt conveyors are highly adaptable to various layouts and configurations. Their flexibility makes them suitable for custom installations tailored to the specific needs of different industries and applications.

Maintenance and Safety Considerations:

Regular Inspection and Lubrication:

Like any conveyor system, circular belt conveyors require regular inspection and maintenance. Components such as rollers and bearings should be inspected for wear, and proper lubrication should be maintained to ensure smooth operation.

Emergency Stop Systems:

Safety features, including emergency stop systems, are crucial in circular belt conveyor designs. These systems provide a quick and effective way to halt the conveyor in case of emergencies or safety concerns.

Future Trends and Innovations:

Integration with Automation and Robotics:

The future of circular belt conveyors involves increased integration with automation and robotics. Conveyor systems may be synchronized with robotic arms for more efficient material handling and assembly processes.

Smart Conveyor Technologies:

Advancements in sensors and data analytics may lead to the development of smart circular belt conveyors. These technologies can provide real-time data on system performance, allowing for predictive maintenance and improved operational efficiency.

Conclusion:

Circular belt conveyors stand as versatile solutions in the realm of material handling, contributing to the efficiency and optimization of various industrial processes. Their space-efficient design, continuous material flow, and adaptability make them indispensable in applications ranging from manufacturing to distribution. As technology continues to evolve, the integration of smart features and automation will likely propel circular belt conveyors into an era of even greater efficiency and sophistication, shaping the future landscape of material handling in diverse industries.

PE Conveyor Belts: Characteristics, Applications, and Advantages

PE Conveyor Belts: Characteristics, Applications, and Advantages

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility